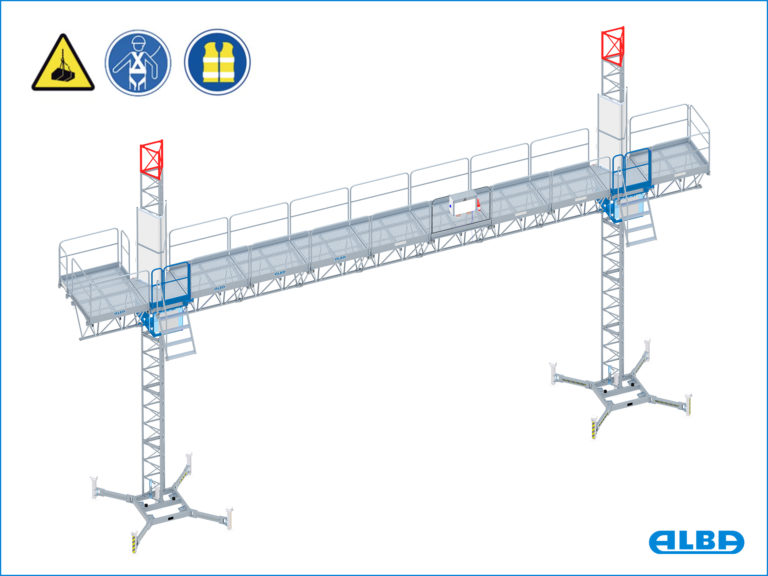

SAFETY TIPS: MAST CLIMBERS

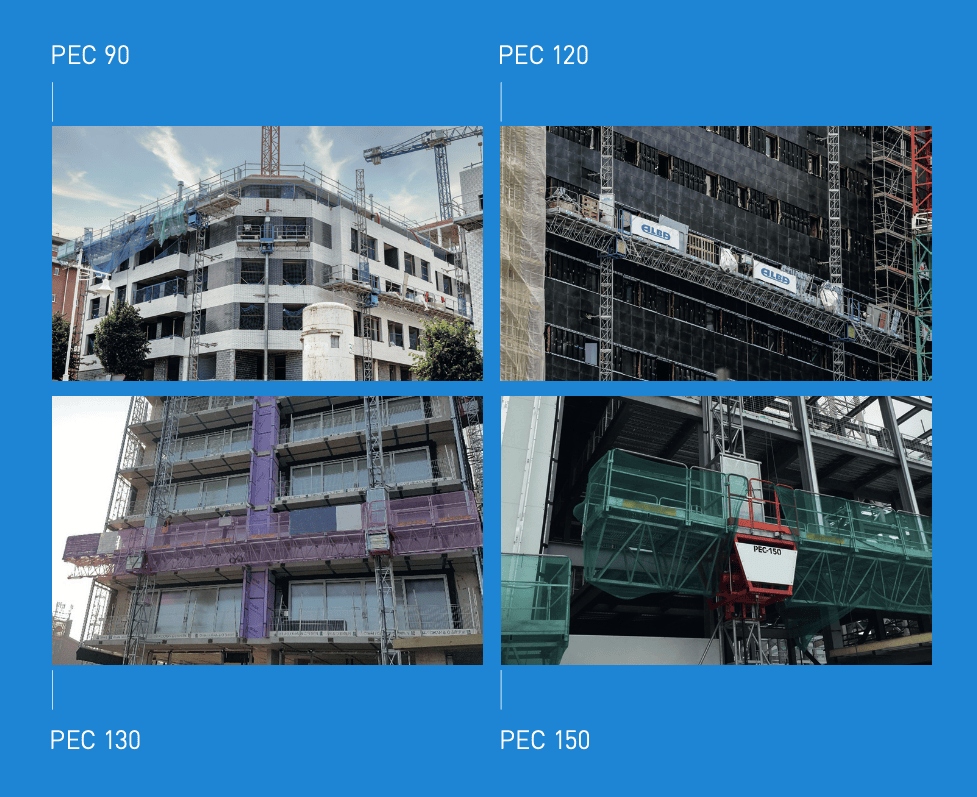

Mast Climbing Work Platforms are the perfect solution for rehabilitation works or façade closings, covering a building perimeter with special extensions up to 2,6 m (corner, zigzag, circular configurations…). These platforms, made of galvanized steel, present benefits in terms of safety that facilitate work at heights in adverse weather conditions.

In addition, the use of the PEC range assumes low electrical consumption relative to its capacities due to the utilization of high-efficiency gear motors and lightweight components. When compared to other lifting alternatives, mast climbers reduce installation and dissasembly time, as well as labor times, which increases productivity.

The electronic/electrical components and the motors of all our hoists are manufactured by European-based International brands, also available in North America. All our work platforms comply with the 2006/42/CE and EN 1495 standards. However, before installing a MCWP, it is advisable to review some general points.

5 safety tips before using a PEC:

1️⃣ Always install guardrails and mast protections.

2️⃣ Use all the required personal fall protection equipment.

3️⃣ Check for hazards such as building protrusions, high-tension lines, uneven surfaces, etc.

4️⃣ Do not alter fastenings, the platform, or the base without authorization from the manufacturer or a competent person.

5️⃣ Anticipate weather conditions and how they may affect the use of the work platform.

Additionally, some aspects about ANCHORING need to be taken into account:

- INSTRUCTIONS MANUAL: consultarlo para conocer la distancia máxima de amarre y las fuerzas de amarre. Estas últimas se calculan en función de la distancia entre los amarres y la distancia entre estos y la estructura, la configuración y la carga de la plataforma, las restricciones de velocidad del viento y otros factores. Consult it to learn about the maximum anchoring distance and the anchoring forces. The latter are calculated based on the distance between the anchors, the distance between the anchors and the structure, the platform’s configuration and load, wind speed restrictions, and other factors.

- LOCATION: a qualified person must approve and detail the anchor locations and where they will be installed. It is important to verify the strength of the concrete and the presence and position of reinforcement steel and tension cables. Consultation with the general contractor or building owner is also necessary to ensure that the planned anchor positions will not cause other issues.

- MATERIAL: the location where the anchors will be inserted must be identical for each anchoring position (e.g., anchoring to a ring beam in the first two or three floors and then anchoring to balcony slabs). Never anchor to wood or brick without authorization from the manufacturer or a structural engineer.

- RNCHOR REINFORCEMENTS: install them correctly. Pay special attention to torque settings and angles of anchor reinforcements. If changes are necessary, they must be authorized by a competent or qualified person, and the details should be registered.

- INSTALLATION: anchor holes must be drilled to the correct depth, and the holes should be cleaned. Use the exact drill bit size specified by the anchor manufacturer and maintain the minimum distance between each anchor and between the edge of the slab and the anchor, as defined in the instruction manual. If there are doubts about the anchor’s performance, a “test” anchor can be installed at the first available anchoring point (e.g., first-floor slab) and a “pull test” performed. An anchor installation should never be abandoned until it is complete.

- DAILY VISUAL CHECK: the integrity of the anchoring system must be verified during the initial ascent.

Click here to see all our models of mast climbers.

Condiciones del suelo

Similarly, verifying that the ground presents optimal conditions is crucial for installing a single or twin-mast platform:

- Verify that the ground beneath the mast and outriggers is well compacted.

- Study the building plans for extended basements, pipe trenches, or drainage channels.

- Regularly inspect the ground around the unit to ensure it remains stable.

- Look above before permanently placing the mast. There may be obstacles that require repositioning.

- Ensure that the mast is not in front of exit doors and that the platform’s travel path does not interfere with anything.

- Level the mast in two directions, parallel and perpendicular to the structure, and once the unit is leveled, ensure that all outriggers are under load.

- Ensure that the position of the base of the zipper platform is not close to traffic routes in the workplace.

And, of course, the most important thing is to consult the instructions manual, where all the necessary details for the correct and safe use of motorized platform lifts will be provided.

ALBA-MACREL GROUP is IPAF (The International Powered Access Federation) member, an organization made up of construction, which promotes the effective and safe use of motorized access equipment worldwide.

?♂️ This allows us to continue working hand in hand with all members of the sector to promote the manufacture of safer and more useful hoists.

? We thus support the creation of new regulations in favor of safety in lifting equipment.